Product Links

Taps and Applications

- Taper Taps - This style with a 7-10 thread chamfer, has the longest chamfer of the three to distribute action over the maximum number of teeth. The taper also acts as a guide in starting the cutting action in blind holes.

- Plug Taps - This style with a 4 - 6 thread chamfer, is most widely used in through holes and where there is sufficient room at the bottom in blind holes.

- Bottoming Taps - This style, with a 1-2 thread chamfer, is made with just enough chamfer for starting in the hole. As the name implies, it is designed to thread blind holes to the bottom.

- Modified Bottoming - Similar to bottoming taps but have 2 to 2-1/2 chamfer threads.

- Semi-Bottoming - Have 3 to 3-1/2 chamfer threads used in blind holes.

Taper Taps - This style with a 7-10 thread chamfer, has the longest chamfer of the three to distribute the cutting action over the maximum number of threads. Sometimes these taps are called "starter" taps and can be used to start the threading of blind holes.

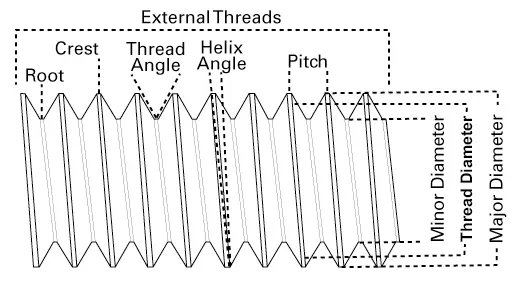

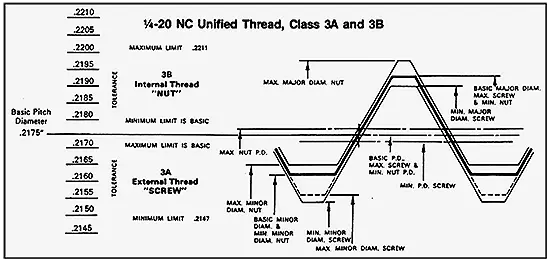

Pitch Diameter - Also called Basic Pitch Diameter, is the basic dimension of a screw, threaded hole or a tap. It is the diameter of an imaginary cylinder, the surface of which passes through the thread where width of thread and space between threads are identical. This cylinder would be a cone for tapered taps. It is upon Pitch Diameter that tolerance limits are based to establish Class of Thread.

Pitch - Equals one divided by the number of threads per inch.

Class of Thread - The standard identification system describing the tolerance and closeness of fit between hole and tap. Defined as A (screws - external), B (nuts - internal), H (metric screws - internal) and G (metric nuts - external). Class 1A and 1B have a loose fit for quick and easy assembly, 2A & 2B have a medium fit, and 3A & 3B have a close fit.

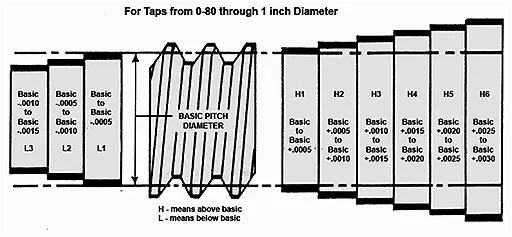

Tap Limit - or GH Numbers is a standardized system to indicate a level of tolerance for the thread outside the basic thread size of the tap. The limits are designated by the letter "H" for inch and "D" for metric, followed by a number. The H limit from one size to the next increases in increments of .0005 of an inch.

| H - 1 | = Basic to Basic + .0005 |

| H - 2 | = Basic + .0005 to Basic + .0010 |

| H - 3 | = Basic + .0010 to Basic + .0015 |

| H - 4 | = Basic + .0015 to Basic + .0020 |

| H - 5 | = Basic + .0020 to Basic + .0025 |

| H - 6 | = Basic + .0025 to Basic + .0030 |

| H - 7 | = Basic + .0030 to Basic + .0035 |

Performance - High performance taps are designed for use on high speed machines in high volume manufacturing environments. General performance taps are for general use in lower volume work with slower speeds.

Substrate - Material which the tool is made. We offer Cobalt-Vandium and High-Speed Steel (HSS) taps.

Coatings - A layer added to the cutting surface of a tool to improve hardness, surface lubricity, and improve tool life.

AlTiN - Aluminum Titanium Nitride. Forms a layer of aluminum oxide at heat increasing its surface hardness and providing better performance where no lubrication is used. Best for steels, cast irons and alloys.

CrC - Chromium Carbide Coated Taps have and advantage over other tap coatings when used in abrasive and corrosive environments. Suitable for steels, cast irons and alloys.

TiCN - Titanium Carbo-Nitride coated taps are similar to TiN coated taps, however the addition of Carbon increase the hardness and improves surface lubricity. TiCN coatings are best used on HSS taps.

Oxide Finish - Also called Black Oxide, is a surface finish that prevents chip building, galling and welding. Oxide coated taps are best when used on low carbon, stainless steels and ferrous metals.

TiN - Titanium Nitride is a general purpose PVD coating that increases the hardness and the oxidation temperature of the tool. Titanium Nitride coatings work very well with HSS tools and is a good coating in steels and cast irons.

Nitride - Is a thin coating that supports surface hardness. Used in abrasive and wearing applications.

Bright (Uncoated) - These taps have a smooth polished finish on the tool for increased chip flow when tapping softer materials such as aluminum, wood and plastic.

Spiral Point Taps

Spiral Point also called Gun Nose or Bull Nose Taps. These taps have a spiral cut longer than the length of the chamfer at the point to help eject chips ahead of the cutting action. The angled edge also provides good cutting performance. They can run at lightly higher speeds than hand taps. These taps have a 4 to 5 thread chamfer and not recommended for blind holes. Available coatings include AlTiN, CrC, Oxide Finish, TiCN and Bright (Uncoated).

For Speed & Feed and other technical information, click here.

Thread Forming Taps

Also known as "fluteless taps", "form taps" or "cold forming taps". Spiral Flute Taps produce threads by displacing material rather than producing chips. Because of their fluteless design thay have more rigidity than fluted taps and have a longer tool life. Spiral Flute Taps are preferred when threading blind holes and perform weill in aluminum, brass, copper, lead, stainless steels, carbon steels and some alloys.

For Speed & Feed and other technical information, click here.

Spiral Flute Taps

These taps will eject chips up and out of the hole being threaded. Use Spiral Flute Taps when threading blind holes in aluminum, brass and softer steels. These high performance taps have available coatings of AlTiN, CrC, Oxide Finish, TiCN and Bright (Uncoated).

For Speed & Feed and other technical information, click here.

Taper Pipe Taps

Taper pipe taps have a tapered angle that helps cutting threads gradually. These are made for exclusive use in tapping pipe fittings. Because of the tapered fitting, these connections will not leak fluid after assembly.

Tip: These taps have to remove a lot of material since you can't drill a tapered hole. Use a tapered pipe reamer to taper the hold before cutting the threads.

Available in National Pipe Thread (NPT), Dryseal American Pipe Thread (NPTF); NPT & NPTF Interrupted NOTE: Interrupted taps have a tooth for every other thread.

Available in TiN, Oxide Finish and Bright (Uncoated) coatings.

For Speed & Feed and other technical information, click here.

Straight Pipe Taps

These taps are designed to create a non-tapered thread for use in National Pipe Straight (NPS) and National Pipe Straight Fuel (NPSF) threads.

Available in TiN and Bright (Uncoated) coatings.

For Speed & Feed and other technical information, click here.

Pulley Taps

Used for creating threads in pulleys for oil caps or set screws. The long reach allows for tapping hard to access holes.

Available as Uncoated only.

For Speed & Feed and other technical information, click here.

Small Shank Extension Taps

For hard to reach holes and when you need to tap longer than the length of the thread on the tap.

Available as Uncoated only.

For Speed & Feed and other technical information, click here.

Screw Thread Insert Taps

STI taps are used for cutting oversized threads for helical coil screw inserts. Where the insert will provide a stronger thread for a balanced distribution of load.

Available as Uncoated only.

For Speed & Feed and other technical information, click here.

Hand Taps

These taps have straight flute so do not direct the chip flow. This can be a problem when using in a machine as the chips can clog the hole your threading. External coolant will greatly assist chip control. These taps are extremely versatile coming a several taper styles including plug and bottom and in different substrate material like HSS and cobalt.

Available in TiN, Nitride, Oxide Finish and Bright (Uncoated) coatings.

For Speed & Feed and other technical information, click here.

.png)