Product Links

Key Cutters

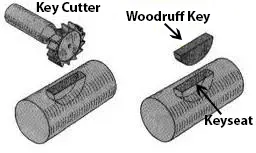

There are two main types of keys that key cutters are used for: parallel keys and woodruff keys.

Parallel Keys

The parallel keyway milling process starts by cutting a simple keyway slot, all the way through the axial diameter of the part. The keyseat is cut into the shaft and the key goes into the keyseat, between both parts forming a secure bond. You could use an endmill to make these cuts but using a key cutter is much easier. Key cutters come in a variety of cutter widths and cutting diameters. Pre-cut key stock is available in standard inch and metric sizes.

Woodruff Keys

Woodruff keys are an alternative to parallel keys. The keys are half-moon shaped and fit into a keyseat shaped as a matching semi-circle that is cut into the shaft. The part that is mated to the shaft has a rectangular slot cut.

Woodruff keys may be full radius or flat bottom but the keyseat will always be radiused by the Key Cutter.

Woodruff keys have several advantages over parallel keys:

- They eliminate the milling near shaft shoulders which reduces stress concentrations and make it easier to maintain circularity constraints

- They are better suited for high speed operation of the rotating shaft

- The key has a more precise fit reducing play and improves the reliability of the key

- A woodruff key may be easier to remove because of its circular profile of the seat. A parallel key requires removal along the axial distance of the seat.

Click the link to browse our inventory.

Key Cutter Speeds and Feeds

| Material | Grades | SFM |

| High Strength Tool Steel | A2, D2, P20, H11, H13, S2, D1 | 80-90 |

| Low Carbon | A36, 12L14, 12L15, 1005, 1018, 1020, 1108-1119, 1213-1215, 1513-1518, 4012, 5015, 9310 | 180 |

| Medium Carbon | 1040-1095, 1140-1151, 1330-1345, 1520-1572, 4023-4063, 4120-4161, 4330-4340, 4620-4640, 8620-8660, 8740-8750, 6150, 51000, 52100 | 170 |

| M - Stainless Steels | ||

| Austenitic | 301-304L, 310, 316L, 321, 347 | 100 |

| Martensitic | 403, 410,416, 420, 430, 431, 440 | 110 |

| Precipitation Hardening | 12/8, 15/5, 17/4, AM-350/355/363, PH13-8M0, PH14-8/M0 | 120 |

| K - Cast Irons | ||

| Ductile | A536, J434, 60-40-18 | 180 |

| Gray | A48, A436, A319, Class 20, G4000 | 140 |

| Malleable | A220, A602, J158 | 100 |

| N - Non Ferrous | ||

| Aluminium Alloys | 2014, 2024, 6061, 7075 | 300 |

| Aluminium High Silicon | A380, A390 | 300 |

| Brass/Bronze | Aluminium Bronze, Low Silicon Bronze | 230-250 |

| Composities | G-10, Firerglass, Graphite, Graphite Epoxy, Plastics | 180-200 |

| Copper | 100-200 | |

| Magnesium | 300 | |

| S - High Temp Alloys | ||

| Cobalt Base | Stellite, HS-21, Haynes 25/188, X40, L605 | 80 |

| Iron Base | Incoloy 800-802, Multmet N-155, Timkin 16-25-6, Carpenter 22-b3 | 80 |

| Nickel Base | Inconel 625/718, Inco 700, 713C, 718, Monel 400-401, 404, K401, Rene, Rene 41 & 95, Hastelloy, Waspoloy, Udimet 500 & 700 | 80 |

| Titanium | Commercially Pure, 6AI-4V, ASTM 1/2/3, 6AI-25N-4Zr-2Mo, Ti-8AI-4Mo | 90 |

Speeds Formula for Calculating RPM

SFM(4) = F

F / Diameter = RPM

EXAMPLE: 1/2" Cutter Diameter in Aluminum

SFM(300) X 4 = 1200(F)

1200(F) / .500 = 2400 RPM

Feeds Formula for Calculating IPM

.001 (# of Teeth in Cutter) RPM = IPM

EXAMPLE: 1/2" Cutter Diameter in Aluminum

.001 X 6 X 2400 = 14.4 IPM